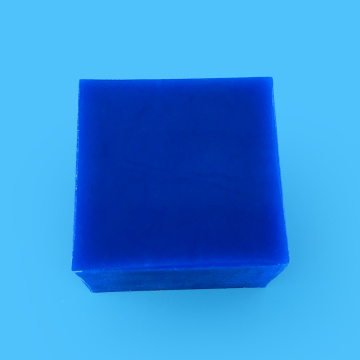

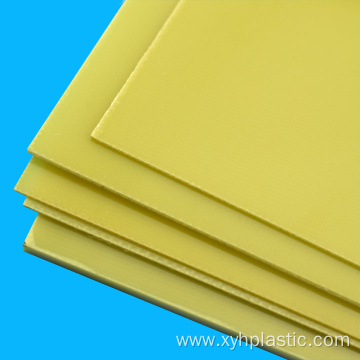

FRP, which stands for Fiber Reinforced Polymer, is a composite material made up of a polymer matrix reinforced with fibers. The polymer matrix can be a thermosetting resin such as epoxy, polyester, or vinyl ester, while the fibers are typically glass, carbon, or aramid. FRP materials are known for their high strength-to-weight ratio, corrosion resistance, and durability. They are commonly used in a wide range of applications, including construction, aerospace, automotive, and marine industries. In construction, FRP composites are often used to reinforce concrete structures, such as bridges, buildings, and pipelines. In aerospace, FRP materials are used to manufacture lightweight aircraft components. In the automotive industry, FRP composites are used to make body panels and interior components. And in the marine industry, FRP materials are used to build boats, yachts, and other watercraft.

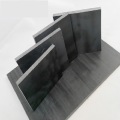

Features Of FRP Sheet

1. High strength: FRP has excellent strength and stiffness and can withstand large loads.

2. Lightweight: Compared with traditional materials such as steel, FRP is lighter, which helps reduce structural load and transportation costs.

3. Corrosion resistance: FRP has good corrosion resistance and can be used for a long time in harsh environments.

4. Insulation performance: FRP is an excellent insulating material and can be used in electrical equipment and power transmission lines.

5. Good design freedom: FRP can be customized as needed, with flexible shapes and sizes.

6. Easy construction: FRP materials are easy to process and install, and can quickly complete construction tasks.

7. Environmental protection: FRP materials can be recycled and reused, reducing the impact on the environment.

8. Low maintenance costs: Because FRP has good durability and corrosion resistance, maintenance costs are relatively low.

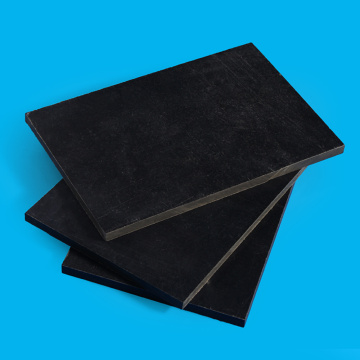

Application Of FRP Sheet

1. Industrial manufacturing: In industrial manufacturing, FRP materials are often used to manufacture various equipment and structural parts, such as storage tanks, pipes, fan blades, ships, etc.

2. Construction field: FRP materials are widely used in the construction field to manufacture exterior wall decoration, roofs, floors, doors and windows and other components.

3. Automotive industry: FRP materials are used in the automotive industry to manufacture body parts, interior parts and body structural parts to improve the lightweight and energy-saving performance of cars.

4. Aerospace: FRP materials are used in the aerospace field to manufacture aircraft, helicopters, satellites and other aviation components to reduce weight and improve flight performance.

5. Energy field: FRP materials are used in the energy field to manufacture wind turbine blades, solar panel brackets and other components to improve the efficiency and durability of energy equipment.

6. Environmental protection field: FRP materials have good corrosion resistance and anti-aging properties, so they are widely used in sewage treatment equipment, flue gas desulfurization equipment, etc. in the field of environmental protection.

7. Sports and leisure products: FRP materials are used in the manufacturing of sports and leisure products to manufacture products such as skis, surfboards, and bicycle frames to improve the strength and durability of the products.